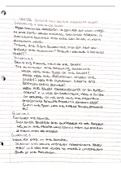

Knet training and summery of each

module With Correct Solutions!!

Planning is performed by the... - ANSWERFirst-line, general, and top-level

supervisors

maintain equipment in good operating condition to - ANSWERmeet production goals,

minimize downtime, and operate production line safely

A Leadman's responsibility is limited to - ANSWERinstructing

The first maintenance organization was a/an - ANSWERline organization

In a functional organization, work is divided according to... - ANSWERequipment

type

An area organization... - ANSWERborrows craftsman as needed

in a centrally controlled organization - ANSWERcontrol is limited in the field, large

projects are handled separately, work is assigned as requests are processed

The written work order used for short duration running repairs is a - ANSWERjob

ticket

There are______________________ types of written orders you could use. -

ANSWERFive types of written orders

Work orders - - ANSWERmajor planned and scheduled tasks

Job tickets - ANSWERShort duration running repairs

standing work orders - ANSWERrepeated job actions

master schedules - ANSWERservice and frequency of work under standing work

order

Special work orders - ANSWERPreventative maintenance

Reserve ______________________ instructions for emergencies, as when a worker

is injured, or a piece of equipment is nearing breakdown - ANSWERVerbal

instructions

It is important for a supervisor to sign the stock issue record T/F - ANSWERfalse

,At different times , maintenance is controlled by the... - ANSWERmaintenance

superintendent

An organization chart - ANSWERcontains all necessary detail

you can overcome resistance to organization changes by - ANSWERadvance

preparation, bargaining, and discussion

Emergencies - - ANSWERwork that must be done immediately

Unscheduled work— - ANSWERrepairs you can delay safely because the equipment

won't deteriorate further.

• Planned and scheduled work— - ANSWERprojects that require much advance

preparation (usually not handled by first-line supervisors).

Which type of maintenance includes the inspection of equipment? -

ANSWERpreventive

scheduling maintenance work is one of the maintenance planners duties t/f -

ANSWERfalse

installing, modifying, and relocating equipment is considered non-maintenance work

and should be funded separately. t/f - ANSWERfalse

the maintenance supervisor can approve schedules for all equipment in the plant t/f -

ANSWERfalse

Project work - ANSWERconstruction, installation, relocation, or modification of

present equipment and buildings

construction - ANSWERbuilding or changing structure of facility

installation - ANSWERinstalling new or rebuilt equipment

equipment modiication - ANSWERmajor changes in existing equipment or facilities

The term maintenance work refers to the repair and upkeep of equipment and

facilities. The work covers preventive maintenance, unscheduled repairs, scheduled

maintenance, emergency repairs, and ______________________ support -

ANSWERfacility

Preventive maintenance - ANSWERmeans any action taken to extend equipment life

or prevent failure before an item malfunctions. It includes inspecting, testing,

lubricating, adjusting, cleaning, and replacing components.

Unscheduled repairs are ______________________ work that can be completed in

less than two manhours. The term also covers work that can be delayed for a short

time with little risk of equipment failure. - ANSWERNonemergency

, Scheduled maintenance refers to major repairs, ______________________, and

overhauls. - ANSWERrebuilds

Emergency repairs - ANSWERare repairs needed immediately

Facility support is a term that covers ______________________work, building and

grounds maintenance, and tool sharpening. - ANSWERjanitorial

unscheduled repairs are usually defined as taking not more than how many

manhours? - ANSWER2

• Adjustments. Minor changes requiring only ______________________ tools, no

parts, and usually less than 0.5 manhours. - ANSWERhand

Backlog - ANSWEREstimated manhours required to complete all work currently

behind schedule. Usually divided into categories according to need: parts and

materials, downtime, manpower, or outside support.

Deferred maintenance. - ANSWERMaintenance you can safely postpone (becomes

part of the backlog).

Equipment repair history. List of repairs made on a piece of equipment that includes

______________________ and cost information. - ANSWERdates

Failure coding - ANSWERList of causes of equipment failure. The causes include

lack of lubrication, operator abuse, and material fatigue, for example.

Inspection - ANSWERChecking equipment to determine needed repairs.

Maintenance work order. A detailed ______________________ request for

maintenance services - ANSWERwritten

Major repairs. - ANSWERExtensive, nonroutine repairs requiring a repair crew.

Minor repairs - ANSWERRepairs completed by one worker using hand tools,

completed in less than two hours. (In many cases, two workers are used for safety's

sake.)

Modification. Change in equipment capability or ______________________. -

ANSWERconfiguration

Overhaul. - ANSWERInspection teardown and repair of equipment to restore it to

effective operating condition.

Planning. Determining the resources and ______________________ needed for a

major job. - ANSWERactions

Priority. - ANSWERListing jobs according to their importance or urgency